The tachometer in your Jeep YJ serves as the vital dashboard companion, providing real-time insights into engine RPM, essential for optimizing performance and ensuring a smooth driving experience. But what if, just as the open road calls, this crucial gauge remains unresponsive?

If the Jeep YJ tachometer malfunctions, diagnose the common issues, including a misaligned needle, damaged wires, faulty fuse, malfunctioning LED, or a worn-out tachometer sensor. Addressing the problem, you can easily restore its functionality. Ensure regular checks to maintain its performance.

In this article, I’ll show you a step-by-step solution to revive your tachometer and ensure your Jeep is back in peak performance.

Understanding the Jeep YJ Tachometer:

At the heart of this iconic vehicle lies its engine, and understanding the pulse of this engine requires you to be acquainted with one of the most essential gauges on its dashboard – the tachometer.\

The Jeep YJ’s tachometer isn’t just another needle on a dial; it’s a window into the very heartbeat of your vehicle.

Designed with precision, this gauge monitors the rotational speed of the engine’s crankshaft, which, in layman’s terms, means it tells you how fast your engine is running.

Displayed in revolutions per minute (RPM), the tachometer gives an immediate visual representation of engine load, efficiency, and safe operating ranges. An engine that revs too high risks overheating and excessive wear, while an engine operating too low may not be reaching its optimal performance level.

A Jeep YJ enthusiast, or any car owner for that matter, should be as familiar with their tachometer as they are with the steering wheel.

Why Monitoring Engine Health is Crucial:

Imagine running a marathon without ever checking your pulse or not knowing how hard your heart is working. Sounds dangerous, right?

Similarly, driving a vehicle without monitoring its engine’s performance can lead to potential hazards and premature wear and tear.

1. Preventing Engine Strain:

The tachometer helps you recognize when you’re pushing the engine too hard. Consistently running at very high RPMs, especially in vehicles like the Jeep YJ designed for varied terrains, can strain the engine, reducing lifespan and potential failures.

2. Optimal Performance:

Every engine has a sweet spot—a range of RPMs where it runs most efficiently, delivering the best performance with the least fuel consumption.

By keeping an eye on the tachometer, you ensure you operate within this optimal range, whether rock crawling or cruising down the highway.

3. Economical Operation:

An over-revving engine consumes more fuel. Using the tachometer as a guide, especially in a manual transmission Jeep YJ, allows you to shift gears at the right moment to maximize fuel efficiency.

4. Safety:

Certain situations, like overtaking another vehicle or navigating steep inclines, require a burst of power. Knowing your current RPM allows you to make informed decisions about gear changes and throttle input, ensuring you have the power you need without pushing the engine into the red zone.

The tachometer is more than just a gauge; it’s a guardian of your Jeep YJ’s engine. It empowers you with real-time data, allowing you to make informed decisions that ensure safety, performance, and longevity.

Signs of a Dysfunctional Tachometer:

An instrument of precision, the tachometer’s role isn’t just about counting revolutions; it’s about safeguarding the engine’s health.

It’s paramount, then, for Jeep aficionados and drivers alike to recognize the early warning signs of a malfunctioning tachometer.

1. Spotting a Stuck Needle:

A tachometer needle that refuses to budge or is slow to respond is one of the first and most overt signs of dysfunction. For a Jeep YJ enthusiast, this should raise immediate concern.

- Cold Start Observations:

Typically, when you start your Jeep, especially in the cold, the needle should momentarily climb before settling. If the needle remains immobile or its movement is lethargic, it clearly indicates a problem.

- Comparative RPM Checks:

Be conscious of the needle’s movement while driving, especially when shifting gears or accelerating. If the engine sound suggests a change in RPM, but the needle remains stationary, it’s time for a closer inspection.

2. Deciphering Erratic Readings:

Sometimes, the tachometer might not be as straightforward in its malfunctioning signals. Erratic readings can be perplexing but are equally indicative of an underlying issue.

- Inconsistent Needle Jumps:

During a steady drive, a well-functioning tachometer should have minimal fluctuation. If you notice sudden and unexplained jumps or drops in the reading, it’s a tell-tale sign of a tachometer issue.

- Discrepancies During Gear Shifts:

The tachometer’s response during gear shifts is predictable for those familiar with their Jeep YJ. Any deviations from this norm, such as the needle failing to drop on upshifts or rise on downshifts, are red flags.

3. LED Malfunctions and Their Indications:

Modern iterations and aftermarket tachometers for the Jeep YJ might employ LED indicators alongside traditional needles. While they offer increased visibility, especially during night drives, they are not immune to malfunctions.

- Fading or Dim LEDs:

If the LEDs seem dimmer than usual or fade in and out, it could indicate a power supply issue or a problem with the LED unit itself.

- Non-responsive LEDs:

LEDs that don't light up at all, especially when the needle indicates a specific RPM range where they should, point towards a malfunction.

This could be due to a failed LED, a wiring issue, or a more complex tachometer malfunction.

How To Fix the Tachometer of Jeep Y.J.:

The Jeep YJ, a beacon of off-road prowess and automotive excellence, is built to withstand both the test of time and the rugged terrains it often graces. Yet, even the most resilient machines are not exempt from minor hiccups.

1. Malfunctioned Needle:

Jeep YJ owners often notice the tachometer needle anchored firmly to the bottom of the gauge, a position it stubbornly clings to even when the engine roars to life. You might think your engine is idling at zero RPM, but the needle is actually playing tricks on you.

It’s not that the tachometer is not functioning, but rather that the needle finds itself on the wrong side of the stop sign, obstructing its movement past the zero mark.

To distill this phenomenon into layman's terms, your needle has lost its correct footing. Instead of poised atop the tiny step at zero, ready to spring into action with the engine's every rev, it's stuck beneath, rendered immobile by its misplacement.

How to Fix:

For those well-acquainted with the Jeep YJ, such a glitch doesn’t demand an immediate trip to the mechanic. More often than not, this issue can be addressed with a careful hand and a keen eye:

- Manual Adjustment:

Turn off the engine and ensure the key is in the 'OFF' position. Using a gentle touch, reach for the needle and rotate it counterclockwise, guiding it to the top side of the stop.

This often rectifies the positioning anomaly and frees the needle to function as intended.

- Tachometer Replacement:

In instances where the needle refuses to cooperate or if you suspect the tachometer itself is compromised, it’s prudent to consider a replacement.

Modern technology has made this process more straightforward than ever, with a plethora of replacement tachometers tailored specifically for the Jeep YJ.

These units, designed to integrate with the YJ's systems seamlessly, typically fall within the price range of $50 to $200, ensuring that quality doesn't necessarily come at a premium.

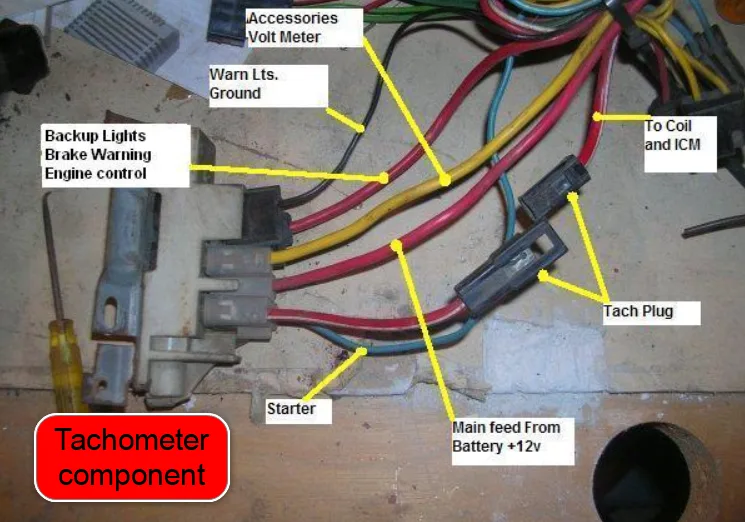

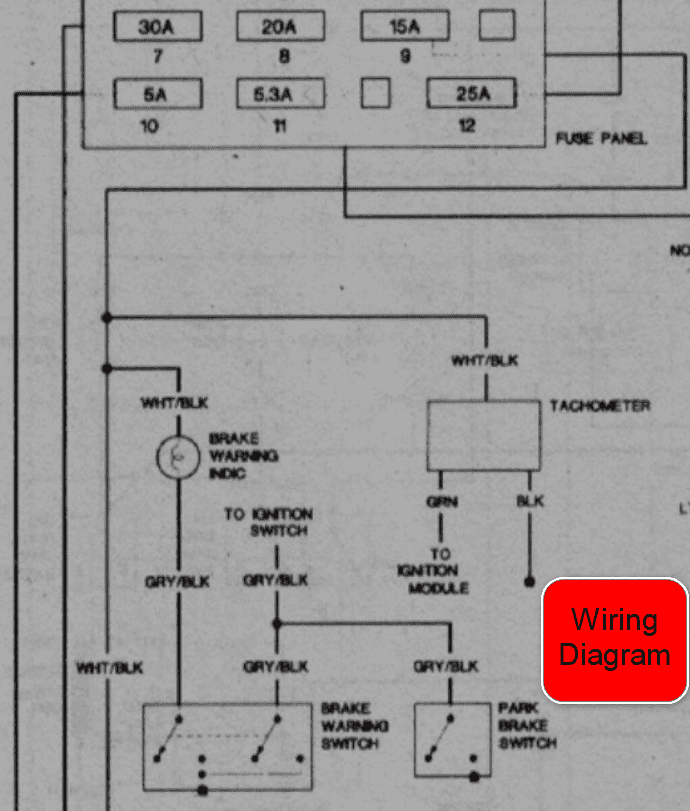

2. Damaged Wiring:

The internal architecture of a tachometer is a delicate ensemble of various components, and the wires, being primary conduits of information and power, are vulnerable to wear and damage.

A compromised wire, be it due to physical damage or electrical anomalies, can manifest in two primary ways:

- Tachometer Failure: The tachometer ceases to operate, leaving you with no RPM reading.

- Display Malfunctions: The tachometer functions but displays erratic or incorrect readings.

Given the inherent logic of electronic systems, a wire or a series of connections are charged with transmitting vital signals to the tachometer.

This transmission is mediated through a wiring sensor and a dedicated wire that connects the Engine Control Module (ECM) or Powertrain Control Module (PCM) to the tachometer, ensuring that the correct voltage reaches its destination.

How to Fix:

- STEP 1- Voltage Stability Check:

Before you dive into more complicated solutions, it’s essential to ascertain voltage stability. A multimeter can be an invaluable tool here.

Discrepancies in the tachometer often stem from voltage irregularities. Over-voltage or under-voltage scenarios can damage the wires, leading to blown wires or insufficient voltage symptoms.

- STEP 2- Grounding Inspection:

The tachometer’s performance is also contingent upon robust grounding. It’s imperative to meticulously inspect the grounding at the tachometer connector nestled within the dashboard.

Any inconsistencies here can lead to display anomalies or complete system failures.

- STEP 3- Professional Intervention:

While many Jeep enthusiasts pride themselves on their DIY acumen, there comes a time when seeking professional expertise is the wisest course of action.

If the tachometer’s internal components demand intricate repairs or replacements, don’t hesitate to consult an expert. While costs can vary, a general estimation pegs the hourly charge of a seasoned mechanic at around $150.

3. Faulty Fuse:

If there’s an overcurrent situation – a surge of electricity more potent than the circuit can handle – the fuse takes the hit, breaking the circuit and preventing damage to integral components.

Now, the tachometer, which measures the speed at which your engine’s crankshaft is spinning, relies on electrical signals to function. A disruption in these signals, often because of a blown fuse, can render your tachometer non-functional.

Diagnosis- Pinpointing the Culprit:

- STEP 1- Visual Inspection:

Begin with a rudimentary visual inspection. A blown fuse often exhibits a broken or charred filament. If the fuse has a clear casing, it becomes relatively easier to spot these signs.

- STEP 2- Use of a Multimeter:

Set your multimeter to continuity mode (often represented by a sound wave or diode symbol). Place the device’s probes on either end of the fuse.

A good fuse will beep or show zero resistance, indicating continuity. In contrast, a blown fuse will show no response.

- STEP 3- Circuit Check:

Ensure that the circuit where the fuse is housed is free from abnormalities, such as short circuits or ground faults. These issues can cause recurrent blowing of the newly replaced fuse.

How to Fix:

- STEP 1- Safety First:

Before diving into the repair, disconnect the Jeep’s battery. This precaution ensures no accidental electrical surges or shocks during the process.

- STEP 2- Remove the Faulty Fuse:

Remove the blown fuse from its slot using a fuse puller. Remember the exact location, as you’ll replace the new fuse in the same slot.

- STEP 3- Insert the New Fuse:

With a fuse of the same amperage rating (this is crucial), insert the new one into the slot. Make sure it sits firmly.

- STEP 4- Reconnect the Battery and Test:

Once the new fuse is in place, reconnect the Jeep’s battery. Start the engine and observe the tachometer. It should now function correctly, provided the fuse was the only issue.

4. Malfunctioned LED:

When your LED screen begins to falter, it often presents itself in forms like:

- Flickering Display: A sporadic blink or inconsistent brightness may indicate voltage irregularities or poor connections.

- Partial Display: If only a section of your LED works, it could be due to individual LED segment failure.

- Complete Blackout: A total failure might suggest deeper issues, such as a malfunctioning circuit or a burned-out LED module.

How to Fix:

- STEP 1- Initial Assessment:

Before diving into the solution, ascertain the degree of damage. Is it a minor flicker? Or has the entire LED screen gone dark? This preliminary diagnosis aids in determining the subsequent course of action.

- STEP 2- Examine the Power Supply:

LEDs rely on a consistent power supply. Use a multimeter to ensure the LED module receives the correct voltage. Any inconsistencies might necessitate a deeper dive into the wiring or the tachometer’s power source.

- STEP 3- Connection Check:

A loose connection might be all that stands between you and a perfectly functioning LED screen. Inspect the wiring, ensuring all connectors are snug and free from corrosion or damage.

- STEP 4- LED Replacement:

If the LED screen is irreparably damaged or malfunctioning, it’s time for a replacement.

- Step 1: Begin by consulting your Jeep’s manual. This invaluable resource will guide you in accessing the LED module within the tachometer.

- Step 2: Once accessed, carefully disconnect the damaged LED unit.

- Step 3: Install the new LED, ensuring all connections are firm. Remember, precision is key. Rushing might lead to further complications.

5. Faulty Tachometer Sensor:

Picture this: the tachometer sensor acts as the translator between the engine’s rhythmic pulses and the tachometer gauge.

Each engine revolution sends a signal to this sensor, which then transmits this data to the tachometer, enabling it to display the RPM in real-time. Without this sensor acting as a bridge, the tachometer gauge would be like a ship lost at sea, devoid of direction and purpose.

How to Fix:

- Preliminary Diagnosis: Begin by establishing the root cause. While a faulty sensor is a common culprit, ensuring other components aren’t at play is crucial.

- Sensor Location and Removal:

- Step 1: Refer to your Jeep YJ’s manual. This treasure trove of information will pinpoint the precise location of the tachometer sensor.

- Step 2: Once located, disconnect the sensor from its harness. Switch off the ignition and take necessary precautions to prevent electrical shocks.

- Acquisition of the New Sensor and Installation: As mentioned, the tachometer sensor for the Jeep YJ is widely available. However, always opt for a reputable brand. Quality ensures longevity and accuracy.

6. Malfunctioned Instrument Cluster:

If none of the previously mentioned solutions prove effective, the final resort might be to replace the instrument cluster.

The instrument cluster is the component housing all the gauges and warning lights in a vehicle, and if it is damaged or worn out, the tachometer may not function correctly.

How to Fix:

Replacing the instrument cluster is a more complex fix that could require a mechanic’s help. However, a Jeep Y.J. owner with some mechanical knowledge can still undertake this task by carefully following the manufacturer’s instructions for installation.

It is crucial to exercise caution and precision during the process to ensure a successful replacement of the instrument cluster.

What’s the Benchmark for a Healthy Tachometer?

The tachometer is more than just a gauge; it’s a dynamic communication bridge between the driver and the engine.

- Steady and Responsive Needle Movement:

A well-functioning tachometer should respond promptly to changes in engine speed. If the needle is sluggish or shows erratic jumps, something is amiss.

- Consistent Zeroing Out:

When the engine is off, the tachometer needle should rest precisely at zero, not wavering or sitting slightly above or below.

- Accurate RPM Readings:

Match the tachometer’s reading with other indicators like the sound of the engine, gear shifts, and acceleration. A healthy tachometer should be in harmony with these cues.

- Illumination Consistency:

The tachometer’s backlight or LED should illuminate uniformly, ensuring readability under varying light conditions. Any flickering or dim areas suggest underlying issues.

- Resistance to External Interferences:

A robust tachometer remains unaffected by external electrical components, such as radio, lights, or other accessories. If you notice fluctuations in its reading when turning on other devices, it’s a red flag.

Analog vs. Digital- Understanding Tachometer Types:

The world of automotive machinery, particularly in the Jeep’s revered domain, embodies tradition and innovation. Just as the Jeep symbolizes rugged versatility, so are its internal components, a blend of time-honored designs and modern advancements.

One such component that has witnessed this evolution is the tachometer. As we journey through the heart of Jeep instrumentation, it’s crucial to distinguish between the two dominant tachometer types: Analog and Digital.

Let me delve deep into their realm, appreciating their nuances and understanding their distinct attributes.

The Timeless Classic- Analog Tachometer:

- Mechanical Essence: Analog tachometers, rooted deeply in mechanical engineering, use an electric motor and gears to move a needle across a calibrated scale. This needle indicates the engine’s crankshaft’s RPM (rotations per minute).

- Visceral Connection: For many Jeep owners, the sweep of an analog needle connects them more viscerally to their vehicle. Watching it move in response to the throttle provides a tactile, real-world feeling, often likened to the rhythmic pulse of a heartbeat.

- Resilience: Analog tachometers, with fewer electronic components, often exhibit a rugged resilience, especially in extreme conditions—making them a fitting choice for the rugged terrain often tackled by Jeep enthusiasts.

The Modern Marvel- Digital Tachometer:

- Precision & Clarity: Digital tachometers display the engine’s RPM through numbers on an LED or LCD screen. This provides a clear and precise reading, leaving no room for misinterpretation.

- Rapid Response: Digital designs can refresh their readings quicker than their analog counterparts, giving the driver an almost instantaneous understanding of the engine’s performance.

- Integration with Modern Tech: Digital tachometers are often easily integrated with other vehicle diagnostic systems. This enables more sophisticated readouts, including data on fuel efficiency, temperature, and more.

Which Reigns Supreme in the Jeep Kingdom?

Neither type can claim a definitive crown. The choice between analog and digital is often a blend of personal preference and specific utility.

- For the Jeep purist who longs for that nostalgic connection with their vehicle, the analog tachometer resonates deeply, echoing the Jeep’s legacy.

- On the flip side, modern Jeep models, geared with state-of-the-art technology, often feature digital tachometers, aligning with the demands of the current generation seeking both performance and convenience.

Final Thought:

In Jeep YJ mechanics’ intricate world, the tachometer is a vital guardian of engine performance. Ensuring its optimal functionality is paramount for both safety and efficient driving.

Armed with a deeper understanding of its components and potential issues, every Jeep YJ owner is now equipped to address and resolve tachometer malfunctions. Drive with confidence, knowing your Jeep’s heart is monitored and beating strong.

Also Read:

Jeep Touch Screen Not Working-How to Fix?

7 Reasons Jeep Wrangler Cruise Control Stops Working (Fixed)

12 Symptoms to Know If Your Jeep Transmission is Bad

Are Jeep Wranglers Good in Winter/Snow? (Detailed Analysis)

7 Reasons My Jeep Wrangler Blower Motor Not Working (Fixed)

Why Does U-Connect Not Work in Jeep? All You Need to Know

Frequently Asked Questions (FAQs):

Is Jeep Y.J. a reliable car?

The 2022 Jeep Y.J. has a predicted authenticity score of 81 out of 100. The predicted reliability score of J.D. Power 91-100 is considered excellent, 81-90 is great, 70-80 is moderate, and 0-69 is fair and considered below average.

Does Jeep Y.J. use a lot of gas?

The vehicle can achieve 22 MPG within the city limits, 31 MPG on the highway, and 26 MPG combined. You should avoid mounting unnecessary costs on the vehicle and avoid sudden acceleration and deceleration to improve your Jeep Y.J. 2022 fuel economy.

Is Jeep Y.J. better than Cherokee?

J.D. Power gave the 2021 Y.J. an overall rating of 78 percent and quality and reliability scores of 82 percent, while the 2021 Cherokee scored 80 percent and 85 percent, respectively. The National Highway Traffic Safety Administration gave both an overall safety rating of four out of five stars.

What are the most common problems with Jeep Y.J.?

We’ve scoured the high and low to find some of the most commonly reported Jeep Y.J. problems owners are experiencing today:

- Suspension problems

- Startup failure

- Wheel bearing failure

- Grinding brakes

- TIPM failure

- Water leaks in the cabin

- Tiger shark engine failure.

How often should I change my Jeep Y.J. oil?

Once the oil change indicator comes on, the manufacturer recommends changing your 2022 Y.J. oil every 500 miles. Change the oil in your vehicle at 10,000-mile intervals or every 12 months, whichever comes first.

This is Surya. I am an experienced off-roader. I have been off-roading for many years across several terrains. I am passionate about 4×4 driving and want to share my knowledge and experience with others.

My goal is to provide you with the most comprehensive and unbiased information about off-roading.

I curated this article through my personal experience and expertise, and I hope it helps you with what you are looking for.

(+91)9123743026

(+91)9123743026

24/1 Nibedita Sarani. M.B. Road, Kolkata- 700051, India

24/1 Nibedita Sarani. M.B. Road, Kolkata- 700051, India