As a Jeep owner, you know these versatile vehicles can be prone to various issues. But one symptom that may fly under your radar is a ticking noise. While it may be tempting to ignore this odd noise, it can be a sign of several different issues.

Several factors, including issues with the exhaust system, spark plugs, low oil pressure in the engine, wear, and tear of valve train noise, faulty purge solenoid, and dry U-joints and CV joints, can cause ticking noise in a Jeep.

In this article, I’ll explore some of the most common reasons why your Jeep may be ticking when accelerating and provide tips for fixing the problem. So if you’re hearing a strange clicking noise from your Jeep, stick around – I’ve got you covered.

Symptoms of the Jeep Ticking Noise:

In the following tables, I’ve provided some common causes of ticking noise in Jeeps, along with the likelihood of each cause.

Please note that this table is not exhaustive, and a qualified mechanic should perform a proper diagnosis to ensure your Jeep is safe and properly functioning.

Symptoms Related to Ticking Noise from the Jeep Engine:

Main Reason | Possibility (%) |

Worn valve lifters | 50% |

Low oil pressure | 30% |

Worn camshaft lobes | 20% |

Symptoms Related to Ticking Noise from the Jeep Suspension:

Main Reason | Possibility (%) |

Worn or damaged ball joints | 60% |

Worn or damaged sway bar links | 30% |

Worn or damaged control arm bushings | 10% |

Reasons Behind the Ticking Noise in Jeep:

The ticking noise in Jeep can occur due to various reasons, as I explained below:

1. Lower Level of Engine Oil or Oil Pressure:

One of the most common causes of a Jeep’s ticking noise is a lower engine oil or oil pressure level. Engine oil is a crucial component in lubricating the engine’s essential components.

Low oil pressure can be caused by various factors, including a faulty oil pump, clogged oil passages, or worn engine bearings.

On the other hand, if the oil level is low, it could be due to an oil leak or oil consumption over time.

When there is not enough oil, metal components rub against each other, leading to friction and power loss. This friction can also create a ticking noise, particularly in the valve train and timing chain.

How to Fix:

If your Jeep is making a ticking noise due to low oil pressure, you can fix this issue by replacing the oil pump or removing the clogging and leaks from the oil system.

Here are some steps which you can follow to fix the low oil pressure and ticking noise:

STEP | Action | Description |

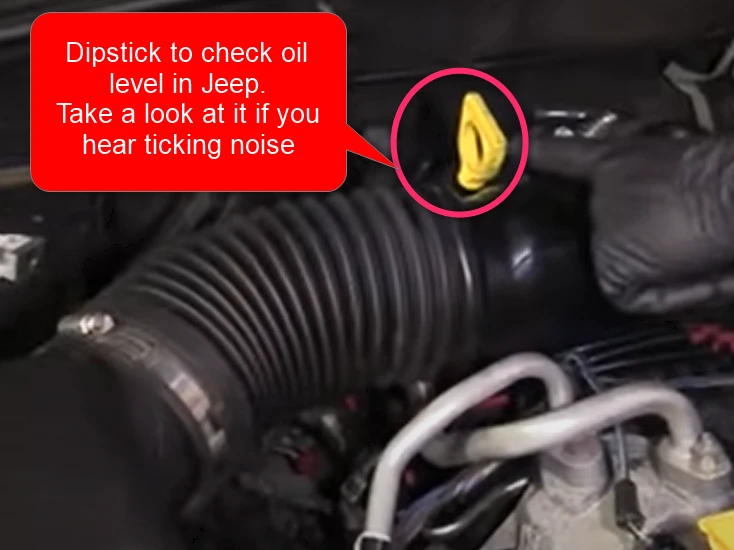

STEP 1 | Checking the oil level | The first step is to check the appropriate oil levels in the vehicle using a dipstick. If the oil level is low, you can bring this level up according to your desired level. |

STEP 2 | Checking the oil pressure sensor | The fault with the oil pressure sensors can give inaccurate readings. You can use a pressure gauge to measure the actual level of oil pressure. If the sensor is broken or needs replacement, you can replace it to fix this issue. |

STEP 3 | Inspection of the oil pump | Next, inspect the oil pump. The oil pump in the vehicle helps circulate the oil throughout the engine. If the oil pump is not functioning, it can produce a ticking noise in the vehicle. |

STEP 4 | Checking the oil filter | The clogging of the oil filter with dirt and debris leads to lower oil pressure in the vehicle, producing a ticking noise. Therefore, keeping the oil filter clean is recommended next to avoid this issue. |

STEP 5 | Inspecting the oil passages | The oil passages sometimes become clogged with dust and debris, reducing their oil flow. It can lead to low oil pressure. It is recommended to keep the oil passage ways clean and remove away the debris before it accumulates in it. |

STEP 6 | Using the correct oil | Next, You need to use the correct kind and grade of oil with proper viscosity for your Jeep. |

2. Misalignment of Valves in Vehicle:

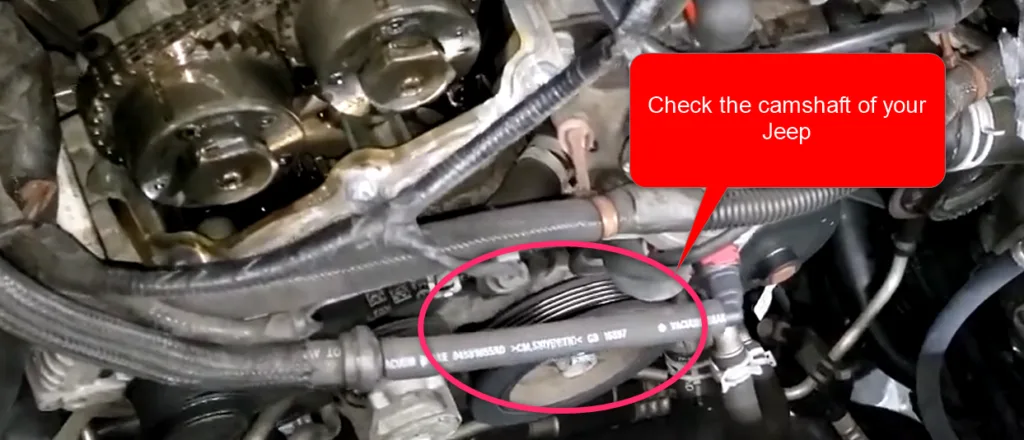

The valvetrains in the Jeep are located near the cylinder head and are responsible for opening and closing the valves. Jeeps have hydraulic valve lifters that take the input from the oil pressure to keep a tight clearance between the camshaft and the rocker arm.

If the oil pressure is incorrect, it can cause problems between the lifters and the drivetrain, leading to a tapping or ticking noise that becomes a concern.

When the engine intake valve opens, air enters via the intake valve. If these valves are not appropriately maintained, it can lead to misalignment and the production of a ticking sound in the vehicle.

How to Fix:

Improper maintenance and wear and tear of the valvetrains can produce a ticking noise which gets annoying with time.

Prolonged issues with the valvetrain can damage the other components, too, including the valve springs, camshaft, lifters, and pushrods.

You can fix the ticking noise by replacing and repairing the valvetrains in the vehicle through the following steps:

STEP | Action | Description |

STEP 1 | Identify the noise | Listen carefully to the engine while running to determine where the noise comes from. Valvetrain noise is typically a ticking or clicking sound that increases the frequency with engine speed. |

STEP 2 | Inspection of valve train | Open the engine's valve cover and visually inspect the valvetrain components for signs of wear or damage. Look for broken or bent pushrods, damaged lifters, worn cam lobes, valves, or valve springs. |

STEP 3 | Replacing the worn or damaged components | If you find any damaged components, you will need to replace them. Depending on the extent of the damage, you may need to replace only one component or several components. It is recommended to replace all the components in the affected area to ensure proper function and longevity. |

STEP 4 | Checking the clearance | Make sure that there is proper clearance between the valve components. Incorrect clearance can cause noise and affect the engine performance. Adjust the clearance, if necessary, according to the manufacturer's specifications. |

STEP 5 | Using the proper amount of oil and additives | Ensure you are using the correct type and grade of oil for your engine. Consider using an oil additive to reduce valvetrain noise. |

3. Misalignment of Lifter:

Misalignment of the lifter can cause a ticking noise in your Jeep. Lifters are small hydraulic components that sit between the camshaft and the pushrods and help to operate the valves.

If the lifter is not aligned correctly, it can cause the valve to open and close improperly, resulting in a ticking noise.

The lifter is typically held in place by a retainer, and if the retainer becomes damaged or worn, it can cause the lifter to become misaligned. This can also happen if the lifter gets damaged or worn over time.

Here let me summarize some possible causes of lifter misalignment in a Jeep:

Possible Cause | Description |

Worn or damaged lifters | Over time, lifters can become worn or damaged, causing them to become misaligned. |

Worn or damaged retainers | If the retainer that holds the lifter in place becomes worn or damaged, the lifter can become misaligned. |

Improper installation | If the lifter is not installed properly during engine assembly, it can become misaligned. |

Engine overheating | Overheating can cause warping or other damage to engine components, which can lead to lifter misalignment. |

How to Fix:

The ticking noise due to the misalignment of the hydraulic lifter can be annoying for the rider. If you can tolerate this noise, there is no need to replace the lifters, but if it creates a disturbance, you can use oil additives to tackle it. It will help eliminate the clicking noise and make your engine much quieter.

On the other hand, you can also replace the damaged or worn components. This may include replacing the lifters, the retainer, or other related components. A proper alignment procedure must also be performed to ensure the lifters are properly positioned.

4. Faulty Spark Plugs:

Spark plugs are small but crucial components of any vehicle’s engine. They play a critical role in igniting the gasoline in the combustion chamber, which powers the engine.

When a spark plug is malfunctioning, it can cause many problems, including a ticking noise. So if you’re experiencing a ticking sound coming from your Jeep’s engine, examining the spark plugs is essential.

When a spark plug is defective in the vehicle and is not seated properly, it leads to a ticking noise. You may also notice other signs of malfunctioning spark plugs, such as a hard engine start, rough idling, poor fuel economy, weaker acceleration, and more misfires.

How to Fix:

The issues with the spark plugs can reduce the performance of the vehicle and can cause ticking noise in the engine.

You can follow the steps I mentioned below to fix the spark plug issues and ticking noise:

- STEP 1: Inspect the spark plugs and detect the damage in them. Look out for the signs like oil deposits on it or the buildup of carbon on the spark plugs.

- STEP 2: After detecting the issue, replace the worn-out or damaged spark plug with a new one. It is recommended to use the correct type of spark plugs to avoid the problem of ticking noise again.

- STEP 3: Remember to check the wiring of the spark plugs. If there is damaged wiring, replace them with new ones to avoid further damage.

5. The Issue with the Rod Knocks in Jeep:

Various components like rod knocks, crankshafts, and others make a ticking noise in the vehicles. Rod knocks are soft metal bearings that transfer energy to the vehicle’s wheels.

There is space between the crankshaft and bearings in the vehicle where the rod moves. When a large space is left without lubrication, it starts to produce an unpleasant noise of ticking which usually indicates low oil levels in the engine.

How to Fix:

This ticking noise is sometimes unbearable for the riders and creates an unpleasant feeling during their adventurous trip.

It is recommended to handle this ticking noise using oil additives, which can be used at the gap in which the rod moves.

Greasing and oil lubrication can make the engine work at peace and will stop this ticking noise in Jeep.

6. Exhaust Leakage in the Jeep:

An exhaust leak can cause external ticking or clicking sounds in your Jeep. The exhaust routes exhaust gases from the engine through the tailpipe.

The exhaust leak can happen when there is a hole or a crack in the exhaust system, letting exhaust gases escape before reaching the tailpipe.

When exhaust gases escape from the exhaust system through a leak, they can produce a ticking or clicking sound.

This sound may be more noticeable when the engine is cold, as the metal components of the exhaust system may expand and contract as they heat up and cool down, causing the leak to open and close.

Various factors, including corrosion, damage to the exhaust system, or improper installation, can cause exhaust leaks.

If left unaddressed, an exhaust leak can lead to decreased fuel efficiency, increased emissions, and potential safety hazards due to exhaust gases in the vehicle’s cabin.

Here’s a table summarizing some possible causes of exhaust leaks in a Jeep:

Possible Cause | Description |

Corrosion | Over time, the metal components of the exhaust system can corrode, leading to holes or cracks in the system. |

Damage | The exhaust system can become damaged due to impacts or accidents, leading to leaks. |

Improper installation | If the exhaust system is not installed properly, it can lead to leaks. |

Wear and tear | The exhaust system can wear down over time, leading to leaks. |

How to Fix:

Exhaust leaks can create a ticking noise in the Jeep, which can be fixed by replacing or repairing the damaged components.

You can follow these steps to fix an exhaust leak in your Jeep that is creating a ticking noise:

STEP | Method | Description |

STEP 1 | Identifying the leakage | The first step in fixing the issue of an exhaust leak is identifying the exact location of the leak. You can check this with a hissing sound or carbon deposits around the pipes or exhaust manifolds. |

STEP 2 | Inspection of exhaust system | The next step is inspecting the exhaust system for signs of corrosion or any other damage. Check out the corrosion or damage near the pipes or exhaust manifolds in the form of cracks or holes. |

STEP 3 | Tightening of connections | Observe the connections of the exhaust leak with the vehicle. If loose, tighten them using pliers or a wrench to prevent exhaust gas leaks. |

STEP 4 | Replacing the gaskets and seals | Check out the head gaskets and seals in the vehicle, and if they are damaged, get them replaced with a new ones. |

STEP 5 | Fixing the patch holes | Look out for the small holes in pipes and muffler or the exhaust. Get them repaired with tape or through a professional mechanic. |

STEP 6 | Replacing the damaged components of exhaust | Look for damage or corrosion in the exhaust system and its associated components. Replace and fix the affected components like pipes, mufflers, and exhaust manifolds if you detect any cracks or holes. |

7. Faulty Purge Solenoid:

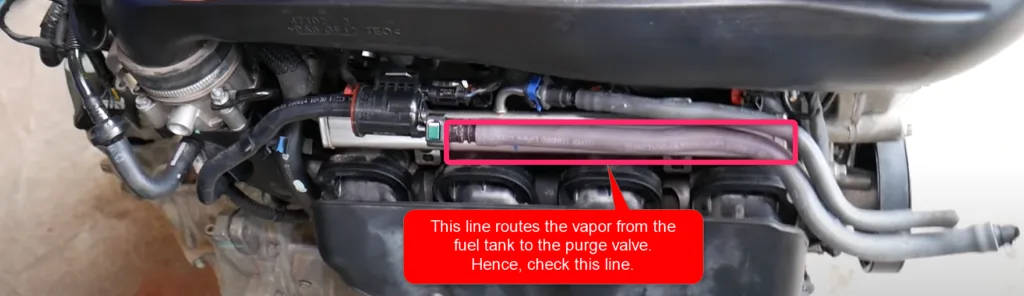

Purge solenoids are a component of the evaporative emissions system in Jeeps. They maintain the flow of fuel vapors to the engine, where they are burned off during regular operation.

A malfunctioning purge solenoid can cause a ticking noise in your Jeep, among other symptoms.

A defective or worn-out valve inside the solenoid causes the ticking noise associated with a faulty purge solenoid.

This valve is responsible for regulating the flow of fuel vapors, and when it becomes worn or damaged, it can cause the solenoid to vibrate rapidly, producing a ticking noise.

In addition to a ticking noise, other symptoms of a faulty purge solenoid may include rough idle, poor fuel economy, and the illumination of the check engine light.

If left unaddressed, a faulty purge solenoid can increase emissions and decrease fuel efficiency.

Here let me add a table summarizing some possible causes of faulty purge solenoids in a Jeep:

Possible Cause | Description |

Dirt and debris | Dirt and debris can clog the valve inside the purge solenoid, causing it to malfunction. |

Electrical issues | A faulty electrical connection or wiring issue can cause the purge solenoid to malfunction. |

Wear and tear | Like any mechanical component, the valve inside the purge solenoid can wear down over time, causing it to malfunction. |

Contaminated fuel | Contaminated fuel can cause damage to the valve inside the purge solenoid, leading to a malfunction. |

How to Fix:

If you suspect that your Jeep’s purge solenoid is malfunctioning, it’s essential to have it diagnosed and repaired by a qualified mechanic.

A mechanic will typically perform a visual inspection of the solenoid and associated components and may also use diagnostic tools to help identify the cause of the problem.

8. Dry U-Joints and CV Joints:

Dry U-joints and CV joints commonly cause ticking or clicking noises in Jeeps. Both joints are part of the drivetrain and transmit power from the engine to the wheels.

When these joints become dry and lose their lubrication, they can begin to produce a ticking noise.

The ticking noise associated with dry U-joints and CV joints is caused by the lack of lubrication between the joint's components.

As a result, the dry components rub against each other as the joint rotates, producing a clicking or ticking noise.

Over time, this lack of lubrication can also cause wear and damage to the joint, leading to more severe problems.

How to Fix:

In some cases, U-joints and CV joints can be lubricated and salvaged, while in others, they may need to be replaced.

Regardless of the approach taken, addressing a ticking noise caused by dry U-joints and CV joints is essential for your Jeep’s safe and reliable operation.

How To Prevent the Ticking Noise on Jeep?

Preventing ticking noise in a Jeep can be achieved through a few essential maintenance and care practices. Here are some steps you can take to help prevent ticking noise in your Jeep:

Regular oil changes:

Keeping your engine oil at the appropriate level can help prevent ticking noise caused by low oil pressure or a lack of lubrication.

It’s essential to follow the manufacturer’s recommended oil change intervals and use the appropriate type of oil for your engine.

Regular maintenance:

Regularly inspecting and maintaining your Jeep’s components, such as the U-joints, CV joints, and exhaust system, can help prevent ticking noise caused by wear and tear.

Keeping the Jeep clean:

Regularly washing and cleaning your Jeep can help prevent moisture, dirt, and other debris from accumulating on critical components, such as the U-joints and CV joints.

Proper driving habits:

Avoiding aggressive driving and rough terrain can help prevent wear and tear on your Jeep's components, which can, in turn, prevent ticking noise.

Addressing problems promptly:

If you notice any ticking noise or other unusual sounds coming from your Jeep, it’s essential to have them inspected by a skilled mechanic.

Upgrading parts:

In some cases, upgrading certain parts of your Jeep, such as the spark plugs or exhaust system, can help prevent ticking noise and improve overall performance.

Following these maintenance and care practices can help prevent ticking noise in your Jeep and keep it running smoothly and reliably for years.

Cost for Fixing the Ticking Noise in Jeep:

The common estimate of costs for fixing the ticking noise in the vehicle is around $70-$150 for an oil change, $75-$80 for oil filter issues, $100-$200 for spark plug issues, $500-$1000 for pushrods and $1000-$2000 for bearings.

Final Thought:

A ticking noise in your Jeep can be a cause for concern. However, the good news is that the most common cause is not a significant issue and can be easily fixed by a mechanic.

It is essential to identify the noise source and work your way through each of the potential causes to determine what needs to be addressed. With proper maintenance and attention, your Jeep can continue running smoothly without any annoying ticking noises.

Also Read:

13 Symptoms of Bad Throttle Position Sensor on Jeep

Jeep Oil Change Required- Meaning and How to Reset

Jeep 4.0 Oil Capacity and Type- All You Need to Know

How to Fix ESP BAS Light on Jeep- All You Need to Know

Jeep 2.0 Turbo: Common Problems to Watch Out For

Most Common Jeep 2.4 Engine Problems- How to Fix

Jeep Grand Cherokee Panoramic Sunroof Problems- How to Fix

Frequently Asked Questions (FAQs):

How can a person fix the ticking noise in the engine?

An off-roader can fix the ticking noise in the engine through the following means:

- Topping up the engine with engine oil

- Using clean oil additives

- Replacing the damaged spark plugs

- Realigning the hydraulic lifters

- Replacing the pushrods of the engine

Why does the Jeep produce a ticking noise during off-roading?

Ticking noise is observed during off-roading due to some internal problems related to the engine and valve train. The valve train of the vehicle includes components like rocker arms, hydraulic lifters, pushrods, camshafts, and other components like cylinder heads.

Does changing the oil in the vehicle stop the ticking noise in it?

Yes, an oil change helps reduce the ticking noise in the vehicle. However, it is better to resolve the underlying cause behind this issue which can be due to the oil leak.

Why does the Jeep produce a ticking noise when the vehicle is accelerated?

A ticking noise is produced when the vehicle is accelerated for various reasons, such as low oil pressure, issues with the ignition system, exhaust leakage, and fault in the spark plugs.

Is the ticking noise in vehicles considered a serious issue?

No, the ticking noise is not a serious issue as it has no concern with the damage to the engine or other components. But, in most cases, this ticking noise can annoy the riders, distracting them during riding.

This is Surya. I am an experienced off-roader. I have been off-roading for many years across several terrains. I am passionate about 4×4 driving and want to share my knowledge and experience with others.

My goal is to provide you with the most comprehensive and unbiased information about off-roading.

I curated this article through my personal experience and expertise, and I hope it helps you with what you are looking for.

(+91)9123743026

(+91)9123743026

24/1 Nibedita Sarani. M.B. Road, Kolkata- 700051, India

24/1 Nibedita Sarani. M.B. Road, Kolkata- 700051, India